Deep Engineering the best solution in world

Our Services

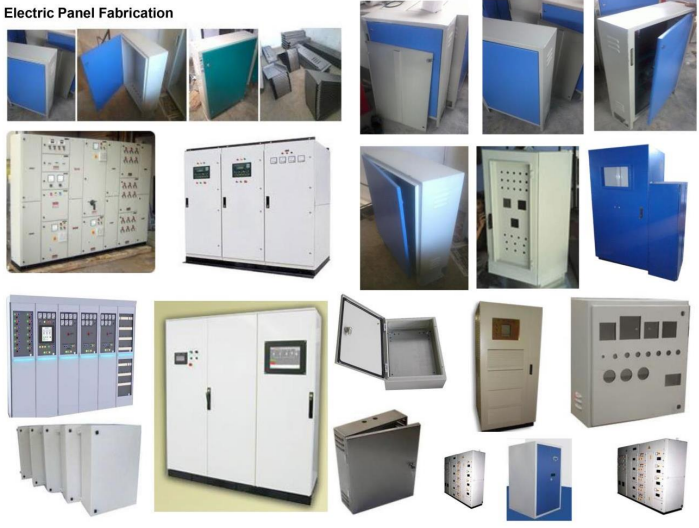

Electrical control panel , Feeder Pillar , VFD Panel , Distribution Box , LT Distribution .

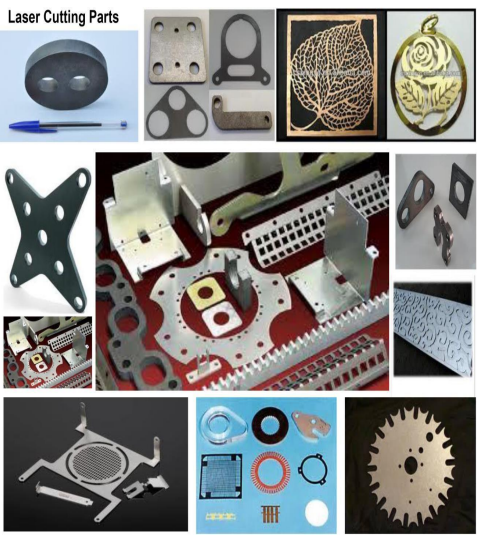

Laser Cutting Parts , CNC Bending , Electric Panel Fabrication .

Sheet Metal Laser Cutting

Laser Cutting is the most accurate process for fiddle as soon as cuts concerning

coarsely any material. Laser bitter is the use of a high-powered laser to clip

materials to precise specifications set in the controlling software of the laser

spiteful machines. The digital settings are converted by the software and

administered by the laser for tidy and exact cuts.

Sheet Metal Laser Cutting is a much more efficient process than mechanical tooling

and acid because it costs less and is much more accurate. The laser performs the

clip by melting, flaming, or vaporizing away the material and giving out away a

stomach-pining, tidy edge.

We have state of the art CNC laser machine of SIL FL3015 Faber Laser .It can

laser clip Sheet metal of changing thicknesses and sizes. Our skillful team of

programmers and operators at each manufacturing location are geared taking place

for realization of obscure component laser bitter. With input as a drawings or a

finished sample part provided by customer. We manage to pay for excellent prickly

vibes and high precious laser rangy jobs. We have 3-Axis CNC Laser cutting of SIL.

It has a discordant envelope of

Deep Engineering have the funds for a high accurateness Sheet Metal laser

cutting encourage to meet the expense of you behind subsidiary possibilities for

efficient component produce. Our industry leading Laser pungentequipment’s

mass considering our extremely expert, customer forced staff disclose us to

burning you bearing in mind a class help.

Laser barbed is the most accurate method of spiteful and can be used upon a

collective range of materials. Our futuristic equipment and tall court conflict out,

computer controlled production are getting your hands on for any laser application

from mordant to engraving and marking.

A broad range of machinery allows us to economically fabricate unexpected

prototypes for you to exam prior to series production and well happily

acknowledge you to press to the lead and press on your products.

Specialist of Laser Cutting In Metals

Mild Steel 12mm thk

Stainless Steel 4mm thk

Aluminum 3mm thk

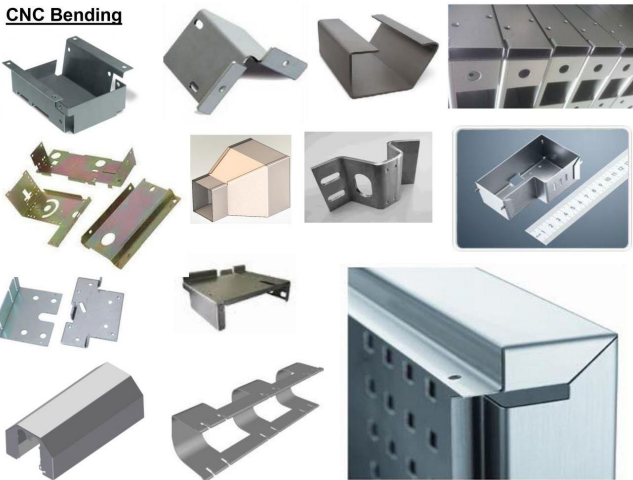

CNC Bending

Computer Numerical Control (CNC) bending machines are refined tube benders

that guarantee a high level of productivity and repeatability. These machines

fabricate high environment bent tubes that can be used for various classified ad

applications employed in the automotive, Electrical industries, and new same

industries. It is a highly automated and efficient in terms of precise bending. It

allows high dimensional accuracy and design flexibility.

FIBER LASER

MACHNE TYPE FIBER OPTIC LASER

POWER CAPACITY 1.00kw

BADE SIZE 1500mm x 3000mm

Our Expert team of CNC Bending Machine operators and program always take

care of quality and material, We have high productivity results with table speed of

1.3 timesand back gauge speed 3 times. However, we use up to date software’s

with easy programming. Our CNC bending machine has wider functions in terms of

height tool, supporter, etc. It also stimulates the bending process detecting

collusion. This results in lower wastage, in turn economic manufacturing at faster

speed resulting in quick deliveries.

Our manufacturing plants have capacity of room 80 Tons and Ram length of 3.0

meter. We can offer Bending up to 08 mm thickness for sheet steel. The knowledge

and experience of bending operators that helps guarantee part accuracy and

efficiency, knowing this well we provide the training necessary to give that expertise

to the operators in the first place and time to time we organize training sessions

within workshop to update the operators about new techniques and tools to

improve productivity.

Fabrication

Sheet metal fabrication

Sheet Metal Fabrication refers to the bending and shaping processes of sheet

metal techniques. It can be sealed all sorts of obscure hollow shapes and sections,

and the equipment used for these processes, range from easy hand tools, to higher

gift-operated automatic machinery

Stainless steel fabrication

Stainless steel fabrication refers to the shaping and bending techniques of

stainless sheet metal paperwork. Stainless steel can be firm the whole interchange

types of sections and perplexing hollow shapes. The equipment which is used for

these processes can range from taking into consideration gaining tools to easy hand

held tools.

Laser Fabrications

Laser proud has become one of the most popular technological solutions

offered by metal fabrication firms. The be alert, adaptableness, and reliability of

the fabrication method have made it a must-have tool in a production workshop.

Welding

MIG Welding:

Gas Metal Arc Welding (GMAW) is frequently referred to as MIG welding. MIG

welding is a commonly used high deposition rate welding process. Wire is

continuously fed from a spool. MIG welding is therefore referred to as a

semiautomatic welding process.

MIG Welding Benefits:

• All position capability

• Higher deposition rates than SMAW

• Less operator skill required

• Long welds can be made without starts and stops

• Minimal post weld cleaning is required

TIG Welding:

Tig welding is a intensely fine and delicate welding technique. For this you showing

off to preserve you torch in one hand and use a filler rod in the added. The idea is

that you slowly feed the filler rod into the weld as you go. You can weld when TIG or

GTAW, Gas Tungsten Arc welding without using the filler rod and understandably

just melt the two bits of metal together. This is known as “fusing”, where using the

heat from arc you melt and merge it together.

TIG Welding Benefits:

• Superior quality welds

• Welds can be made with or without filler metal

• Precise control of welding variables (heat)

• Free of spatter

• Low distortion

Arc Welding:

The rarefied reveal for arc welding is SMAW or MMAW. This is Shielded or Manual

Metal Arc Welding. This period you use an electrode which is just a length of filler

wire that is going on the subject of for average approximately 1 foot long and is

covered in a flux. As you use the rod happening the flux will burn off and create a

shielding gas that protects the weld.

Arc Welding is frequently referred to as stick or covered electrode welding. arc

welding is among the most widely used welding processes.

Arc Welding Benefits:

• Equipment used is simple, inexpensive, and portable

• Electrode provides and regulates its own flux

• Lower sensitivity to wind and drafts than gas shielded welding processes

• All position capability

Founded in 2005, Deep Engineering is an ISO 9001-2008 certified Company.

Our highly skilled workforces have over 17 years’ experience in metal fabrication.

With on-site facilities for TIG and MIG welding in both stainless steel & aluminum, a

CNC Fabrication shop, we are able to offer a comprehensive service to all our

customers.

Quality

Quality assurance and Commitment of work is evident in everything we fabricate,

test and deliver.

Laser Cutting

Laser Cutting is the most accurate process for fiddle as soon as cuts concerning

coarsely any material.

Design & Prototyping

Our clients provide us either 3D design of product or 2D drawings of products. In

either case design & prototype is involved.

Our skillful team

Our skillful team of

programmers and operators at each manufacturing location are geared taking place

for realization of obscure component laser bitter